Sales

We use different principles for load application. Depending on the test assignment, we will advise an appropriate principle.

Factors influencing choise:

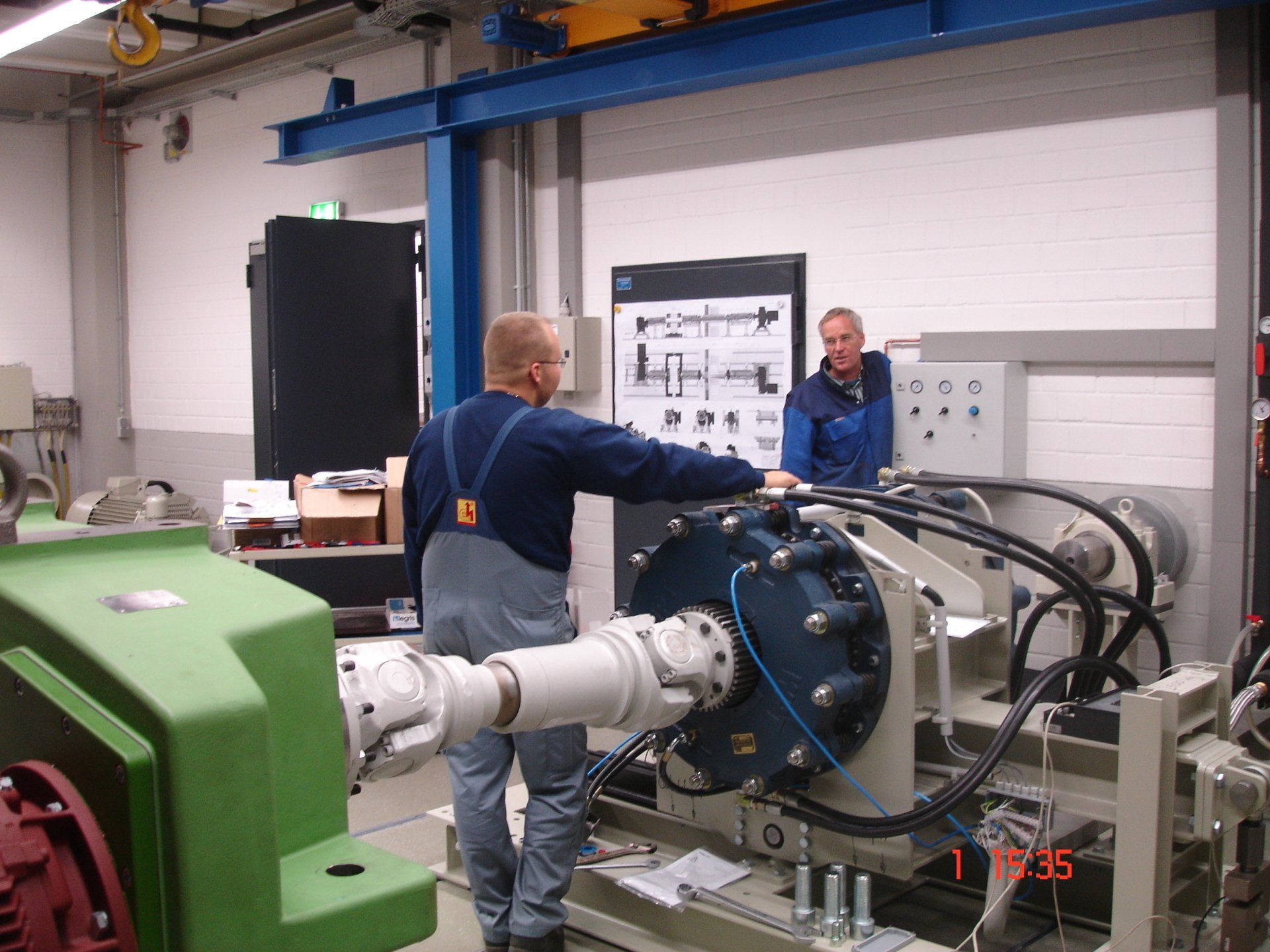

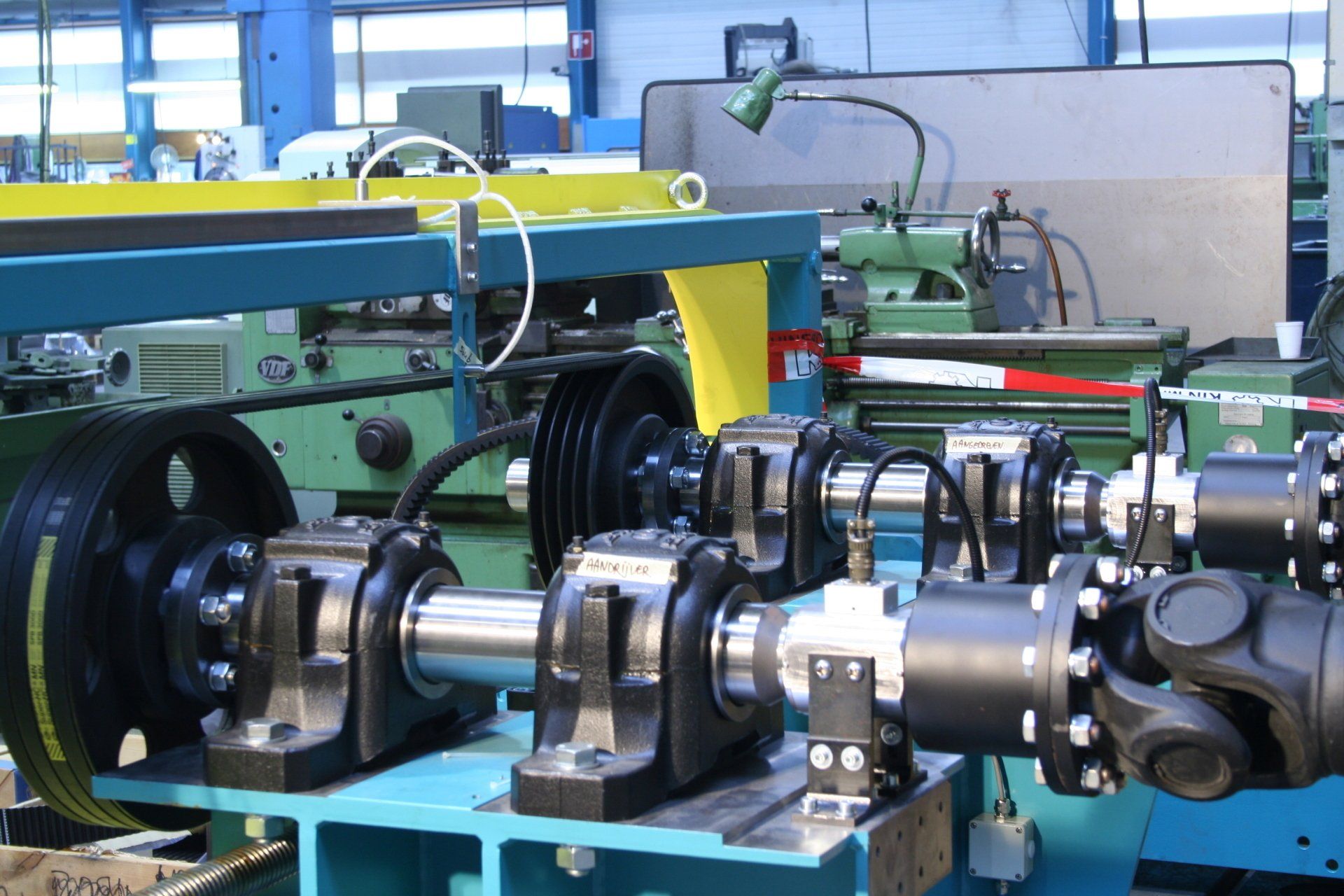

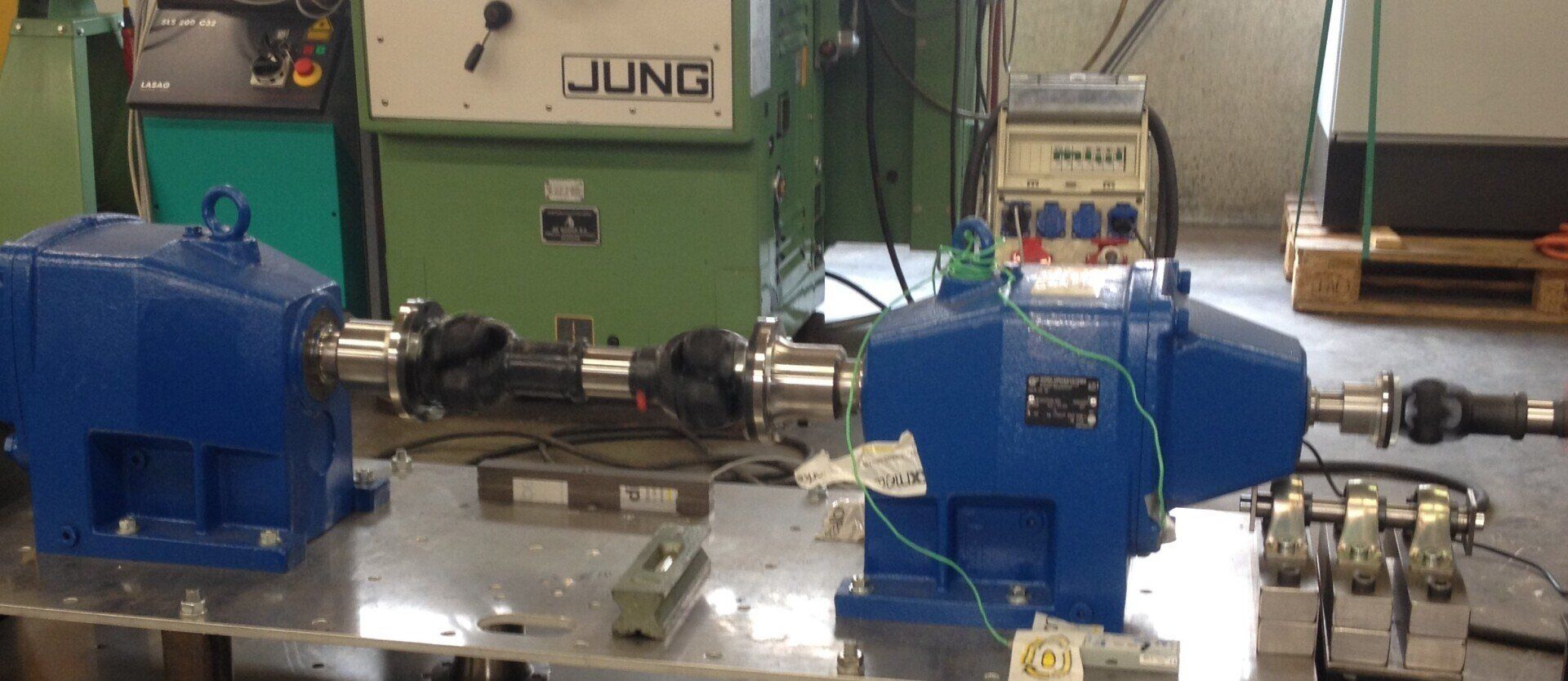

Component

motor, gearbox, reducer, belt, chain, clutch, etc.

Load range

Range of rotation speed

Power range

Operating hours

Type of user

Test engineer versus production worker

Grade of automation

Type test

Production test, product development test, etc.

Purpose of the test

Check torque / speed, determine efficiency, etc.

Based on your challange and a (telephone) conversation, we make an estimate of the best option for your specific test assignment. We will discuss this with you. Based on the outcome we can make an offer.